Mix15L

Create_time:2023-08-17 Views:28947

Pasteurization

Low temperature pasteurization: heating to 65°C and keeps for 30 minutes.

Medium temperature pasteurization: heating to 75°C and keeps for 15 minutes.

High temperature pasteurization: heating to 85°C and keeps for 2 minute.

Fully automatic control system:

When heating and pasteurizing process is completed, a sound beeps and it automatically turns to cooling procedure.

The final cooling temperature maintains at 4°C.

The overall operation takes an hour.

Three operations in ONE button –pasteurizing + homogenizing + aging.

Fully automatic control: start heating to 85℃, then rapidly cool down to 4℃ and keep temperature constantly at 4℃ for aging treatment. Specific heating and cooling temperature can be set freely.

Creamy taste guaranteed: the mixing and shearing system makes raw material into very small particles, and the homogenization system greatly improve the emulsification effect, which is the key to manufacture high-quality ice cream.

Energy saving design: Mix tank’s lid was made with thermal insulation device saves energy.

Capacity: This machine can handle 8 to 14 liters of raw materials.

Power specification: 380V/3/50Hz, 220V/3/60Hz, 220V/1/60Hz or 50Hz

Power: 3.5kw

Refrigeration system: 1.5HP (American or French brand)

Cooling system: water cooling or air cooling (air cooling comes with a surcharge)

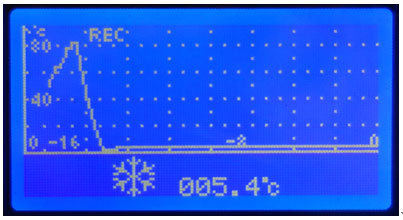

The screen displays the process status with records of time and temperature curve for checking.

Operation sound reminder: When heating to 40℃, a sound beeps to remind for adding powder, such as ice cream base and sugar. When cooling to 60℃, a sound beeps to remind for adding heavy cream.

Double speed and automatic switch mechanism: Double speed allows low-speed mixing and high-speed homogenizing. When heating temperature reaches 55℃, machine automatically switches to high-speed to chop and extrude raw material into smaller and more identical structure for better homogenization effect.

Automatic cleaning button: Press the button to activate a two-minute cleaning process.

Raw materials are cut through the high-speed rotor and squeezed into the holes on the stator at high speed.

When they are repeatedly squeeze through small holes, homogenization occurs and greatly improve the emulsification effect, which is the key to produce high-quality ice cream.

The speed of the rotor can be optional adjusted to high speed or low speed as required.

Three-piece sandwich stainless steel barrel covered with thermal insulation device saves energy.

Product parameters

|

Model |

Mix15L |

Mix30L |

Mix60L |

Mix140L |

|

|

Capacity(Liter) |

15 |

30 |

60 |

120 |

|

|

Mix Capacity(Liter) |

8~14 |

12~28 |

20~58 |

50~115 |

|

|

Production(Liter) |

15 |

30 |

60 |

120 |

|

|

Process Time(Maximum Mix Capcity)/Min |

60~80 |

100~110 |

110~150 |

180~210 |

|

|

Power Type |

380v/3/50 Hz |

380v/3/50 Hz |

380v/3/50 Hz |

380v/3/50 Hz |

|

|

220v/3/60 Hz |

220v/3/60 Hz |

220v/3/60 Hz |

220v/3/60 Hz |

||

|

Refrigeration System |

1.5hp |

3hp |

3.5hp |

5hp |

|

|

Power |

3.5 kw |

4 kw |

5 kw |

11 kw |

|

|

Dimensions/ mm |

Width |

410 |

410 |

510 |

660 |

|

Depth |

790 |

790 |

960 |

1020 |

|

|

Height |

900 |

1090 |

1090 |

1150 |

|

Finished Products

- Prev:Mix30L